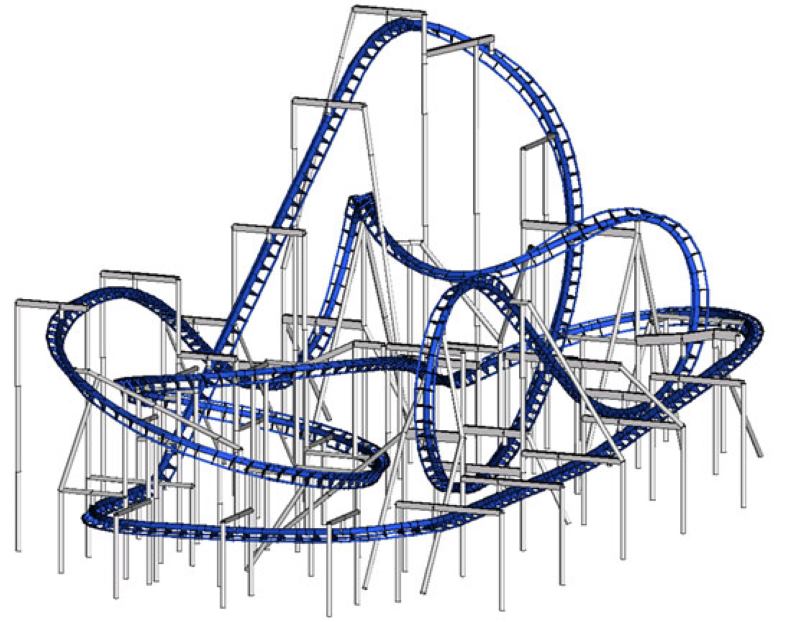

Qihe Amusement Park Roller Coaster Steel Structure

Qihe Amusement Park Roller Coaster Steel Structure

Project Basic Information

Project Name: Qihe Amusement Park Roller Coaster Steel Structure Production ProjectClient: Mack Rides Company, Germany (Engineering Party)

Owner: Shandong Kunhe Tourism Development Co., Ltd.

Contractor: Our Company (ZHM)

Project Location: Qihe County, Shandong Province, China

Technical Parameters and Standards

| Category | Content |

| Steel Structure Tonnage | 266 tons |

| Material Standard | China National Standard (GB) |

| Manufacturing Process |

- EN 1090 (EU Steel Structure Certification) - EN ISO 15614-1 (Welding Procedure Qualification) - EN ISO 15613 (Assessment Based on Pre-production Testing) - GB (China National Standard) |

Delivery Time: March 2013

Total Construction Period: 4 months (Winter construction, tight schedule)

Project Background

1. Major Project:

Yellow River Ecological Tourism and Cultural Park (Key Project in Shandong Province)

Total Investment: 11.6 billion RMB

Subproject: Qihe Amusement Park Roller Coaster Facilities

2. Client Requirements:

Mack Rides Company adopts cutting-edge European roller coaster model design to create an international-level theme park experience.

ZHM undertakes its steel structure manufacturing and installation, needing to simultaneously meet both Chinese and European standards (EN and GB).

Project Highlights

International Collaboration: Integration of German technical standards (EN series) with local Chinese manufacturing (GB).

Efficient Execution: Completion of 266 tons of steel structure within 4 months (including harsh winter construction).

Technical Challenge: Simultaneously meet EN 1090 (EU's highest steel structure certification) and national standard requirements, reflecting precision in craftsmanship.

Project Significance

Assist Shandong Province in building a world-class tourist destination (Yellow River Ecological Tourism Cultural Park).

Demonstrate China's manufacturing capability in undertaking international high-end entertainment facility projects (through strict acceptance by the German side).

The processing of roller coaster steel structures is a typical high-precision, high-safety special steel structure project. The key difficulties mainly manifest in the following aspects, analyzed in conjunction with this project (EN1090 + GB dual standard certification, winter construction, three-dimensional curved surface structure):

1. Core Difficulty Analysis

1. Three-Dimensional Curved Surface Precision Control (Core Difficulty)

Challenges of this project:

The German model includes high dynamic load design, and the track surface precision directly affects the smoothness and safety of roller coaster operation.

There are differences in the surface fitting requirements between national standards (GB 50755) and European standards (EN 1090-2), requiring dual compliance.

Solution:

A [Three-Dimensional BIM Model Decomposition] --> B [CNC Precision Cutting]

B --> C [Special Frame Pre-assembly]

C --> D [Total Station Real-time Coordinate Calibration]

D --> E [Laser Tracker Re-measurement]

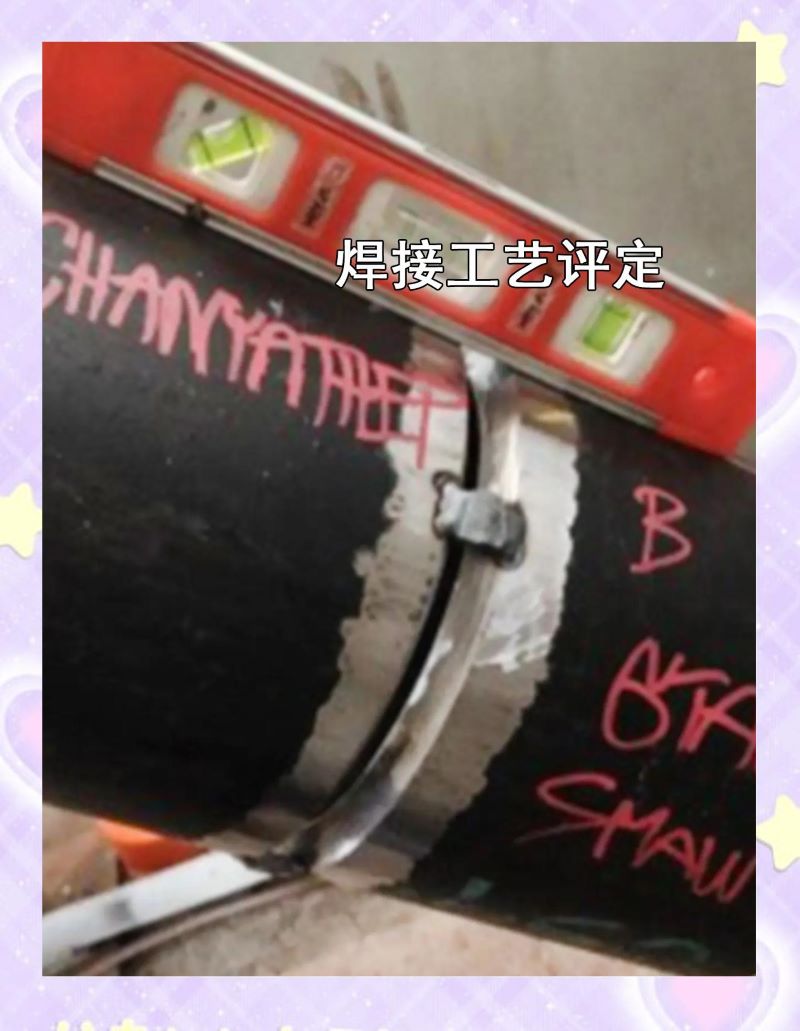

2. Dual Certification of Welding Process (Technical Barrier)

Key Requirements:

EN ISO 15614-1: Must pass EU welding procedure qualification (WPS/PQR), covering low-temperature toughness testing (-20℃ impact).

GB 50661: Simultaneously meet national standard non-destructive testing Level I for welding joints.

Difficulties of this project:

Winter construction (2012.12-2013.3): The low-temperature environment in Shandong during winter poses a threat to welding quality.

The material is national standard Q345B but needs to match the performance of European standard S355J2; welding material selection requires dual certification.

Control Measures:

Build a temperature-controlled welding shed (ambient temperature ≥ 10℃).

Use narrow gap submerged arc welding to reduce heat input deformation.

100% UT + MT testing (European standard EN ISO 17640 + national standard GB/T 11345).

Special Load: The operation of the roller coaster generates alternating impact loads (≥5g acceleration), and nodes are prone to fatigue failure.

Key nodes execute EN 1993-1-9 (EU Fatigue Design Code) for finite element fatigue analysis (FEA).

Bolt connections use HV10 grade high-strength bolts (anti-loosening design).

Manufacturing Control:

Forced assembly is prohibited to eliminate assembly stress.

Hammer stress relief at track joints (in accordance with EN ISO 15614-1 Appendix D).

II. Key Process Control Points

Control Link

European Standard (EN) Requirements

National Standard (GB) Requirements

Integration Control Measures

Material Certification

EN 10025-2 S355J2

GB/T 1591 Q345B

Customized Z-direction performance plate (Z15) from steel mill

Dimensional Tolerance

EN 1090-2 Class 2

GB 50205-2020 Class A

Dual assurance with laser scanning + CNC correction

Anti-corrosion Coating

ISO 12944 C5-M corrosion level

GB/T 30790

650μm epoxy zinc-rich primer + polyurethane topcoat

Non-destructive Testing

EN ISO 5817 Class B welds

NB/T 47013-2015 Class I

Full coverage with TOFD ultrasonic diffraction time difference method

1. Winter Construction Risks

Steel preheating to above 120°C (infrared temperature monitoring).

Post-weld slow cooling (insulation cover for ≥2 hours).

2. Differences in Central European Standards

Preparation of dual-standard compatible process documents (with written approval from Mack Rides).

German supervision on-site throughout (joint visa at key nodes).

3. Schedule Compression (4 months)

Modular prefabrication of track segments (36 transport units).

Ground pre-assembly rate ≥90%, reducing high-altitude work.

A[German side provides parametric model] --> B[ZHM in-depth design]

B --> C[CNC precision cutting and blanking]

C --> D[3D frame positioning and welding]

D --> E[German supervision online inspection]

E --> F[Thermal spray aluminum anti-corrosion treatment]

F --> G[Sea transportation to European amusement park]

Project Outcome: 266 tons of steel structure passed the German TÜV EN 1090 EXC3 certification (the highest level in the EU) in one go, becoming the first large amusement facility steel structure project in China to pass this certification. This case proves that under stringent dual-standard requirements, Chinese manufacturing can achieve technological breakthroughs in "precision heavy industry," laying the foundation for ZHM Huawu Steel Structure to undertake international high-end amusement projects in the future.

Why ZHM Huawu Metal Amusement Park Roller Coaster Steel Structure?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Amusement Park Roller Coaster Steel Structure? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com