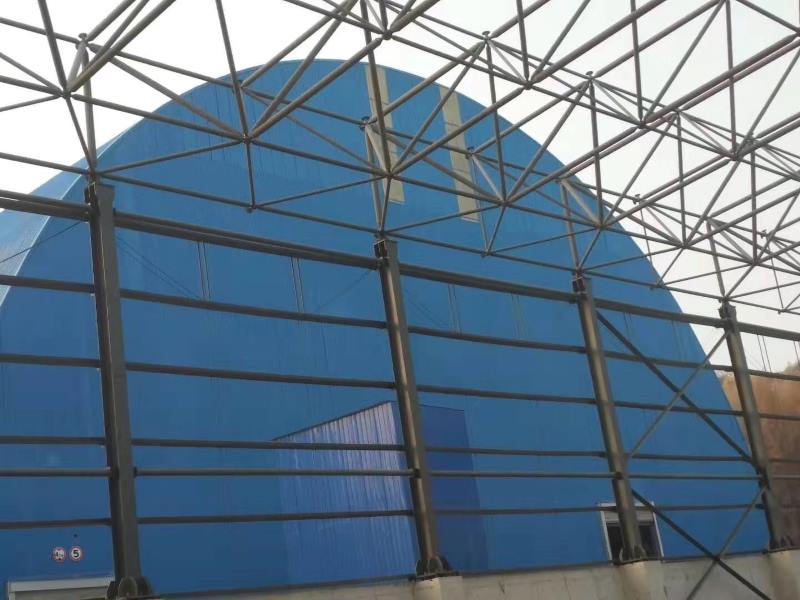

Jilin Yongji Jinyu Storage Shed Grid Space Framework

Structural Form

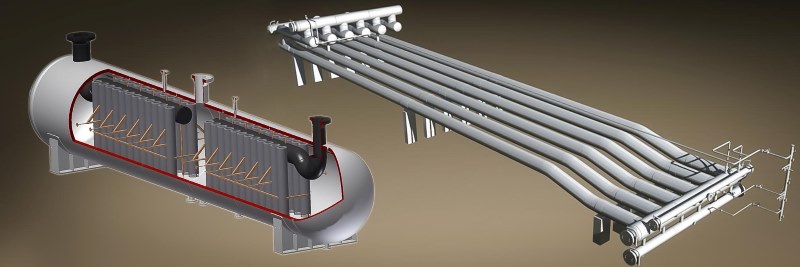

Bolt ball joint framework (suitable for spans of 30-60m, high standardization, quick installation)

Double-layer upright four-corner cone framework (good stability, suitable for northern snow loads)

Local reinforcement design: add truss support at the storage shed entrance (for wind pressure requirements)

Snow Load: Yongji County ≥ 0.75 kN/m² (needs verification for uneven snow distribution conditions)

Wind Load: Basic wind pressure 0.55 kN/m² (considering winter monsoon effects)

Seismic: 7-degree protection (0.10g)

Corrosion Protection: Hot-dip galvanizing (≥80μm) + fire-retardant coating (fire resistance limit 1.5 hours)

Advantage Reference Case Distance by Car from Yongji

Direct supply of Q355B steel from steel mill, price advantage Tonghua Steel Storage Shed Framework 2 hours

Equipped with CNC intersecting line cutting machine FAW Logistics Warehouse 1.5 hours

Focus on large-span bolt ball frameworks Shenyang Free Trade Zone Storage Shed 3 hours

Rich experience in construction in cold regions Harbin Grain Storage 4 hours

Key Construction Processes and Schedule

A[Geological Survey] --> B[Foundation Embedded Parts Construction]

B --> C[Framework Ground Assembly]

C --> D[Segmental Hoisting (or Overall Lifting)]

D --> E[High-strength Bolt Tightening]

E --> F[Purlin and Roof Panel Installation]

F --> G[Corrosion Coating Repair]

Processing: 1000 tons scale about 45 days (winter requires heated workshop)

Installation: 30m span standard unit, daily progress ≥ 300㎡

Cost Control Suggestions

Material Optimization

Main Material: Q355B steel pipe (wall thickness 4-8mm, reduces weight by 10-15% compared to Q235)

Joint: Bolt ball (saves 25% in labor costs compared to welded balls)

Project Unit Price Range Remarks

Framework Processing 750-1400 yuan/ton Includes bolt balls/welded balls

Installation Fee 200-450 yuan/ton Includes crane rental (winter +20%)

Galvanizing and Corrosion Protection 800-1200 yuan/ton Includes transportation to Jilin

Roof Panels 60-120 yuan/㎡ Suggest using YX51-380 type panels

Winter Construction Precautions

Welding rods need to be dried (350℃×1h), stored in insulated buckets on site

High-strength bolts are prohibited from being tightened below -10℃ (must be preheated to above 0℃)

Concrete Foundation

Add antifreeze (ensure foundation strength ≥ 70% of design value before installation)

Safety Measures

Anti-slip scaffolding (lay anti-slip mats)

Check hoisting steel wire ropes before starting work each day (risk of brittle fracture in low temperatures)

Project Testing and Acceptance Standards

Mandatory Inspection Items

Weld seam UT testing (sampling ratio ≥ 10%)

Bolt ball tensile test (3‰ sampling)

Deflection measurement (after loading ≤ span of 1/250)

Acceptance Specifications

"Quality Acceptance Standards for Steel Structure Engineering Construction" (GB50205-2020)

"Technical Regulations for Spatial Grid Structures" (JGJ7-2010)

Why ZHM Huawu Metal Storage Shed Grid Space Framework?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Storage Shed Grid Space Framework ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com