Ultra-Large Span Steel Roof Structure Xiamen Taikoo Aircraft Hangars

ZHM Huawu Steel Structure utilizes "Four New" technologies to assist in the intelligent construction of large hangar airports.

From June 18 to 19, the Forum on Technological Innovation and Development of Large Hangars and Airport Engineering, along with the Technical Exchange Conference on New Energy Applications for Large Public Buildings under the Dual Carbon Background, was held in Fujian. Over 300 experts and scholars with rich experience and research achievements in the field of hangar and airport engineering attended, including Academician of the Chinese Academy of Engineering and Chief Expert of China State Construction Group, Xiao Xuwen, and Academician of the Chinese Academy of Engineering and Chief Architect of Shenzhen Architectural Design and Research Institute Co., Ltd., Meng Jianmin. They engaged in discussions based on typical engineering practices, focusing on green construction, intelligent construction, and the design and construction technology of complex large airports and hangars. Chief Engineer of ZHM Huawu Steel Structure, Qi Ligang, attended the conference and delivered a speech.

During the event, guests and leaders visited the ZHM Huawu Steel Structure maintenance base project at Xiamen Taikoo Xiang'an New Airport and the first section of the terminal area project at Xiamen Xiang'an Airport, where they observed ZHM Huawu Steel Structure's experiences and achievements in technological construction and quality construction, and learned about the project's innovative practices and technological accomplishments.

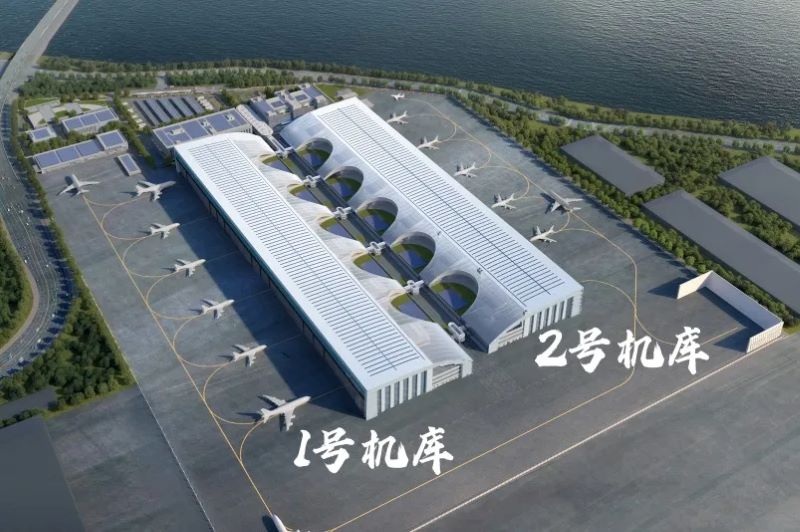

Xiamen Taikoo Xiang'an New Airport Maintenance Base Project

The Xiamen Taikoo Xiang'an New Airport Maintenance Base Project covers an area of 537,300 square meters, with a total building area of 292,300 square meters, including 12 large aircraft maintenance positions and 6 narrow-body maintenance positions. Hangars 1 and 2 are the core parts of the entire project.

The steel structure roof of Hangar 1 measures 525.1 meters in length and 73.85 meters in width, with a projected area of approximately 38,800 square meters and a weight of 11,393 tons. The maximum single-span of the steel structure roof reaches 269.5 meters, making it the largest single-unit civil aviation aircraft maintenance hangar in the world. To elevate this "iron giant" 27 meters for high-altitude docking, the project innovated and applied multiple technologies.

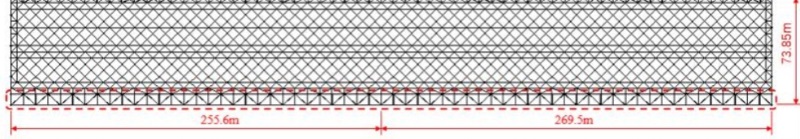

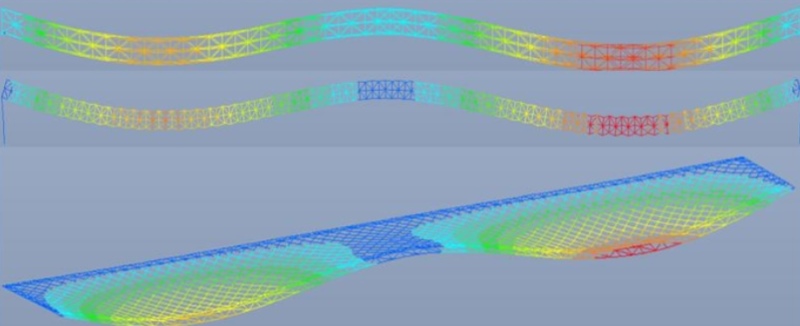

New "Wedge-Shaped Thick Plate" Roof System

During the design process of the large-span roof, the project team broke through the traditional design layout of short-direction force transmission. Based on the elongated (1:7.2) characteristics of the roof's plan, they adopted the long-direction force transmission "wedge-shaped thick plate" roof system for the first time, solving the deflection control problem of the 269.5-meter + 255.6-meter ultra-large-span heavy roof, meeting the operational needs of suspended equipment weighing thousands of tons, and efficiently advancing the construction of the steel structure.

▲ Figure Roof Truss Structure Plan Layout

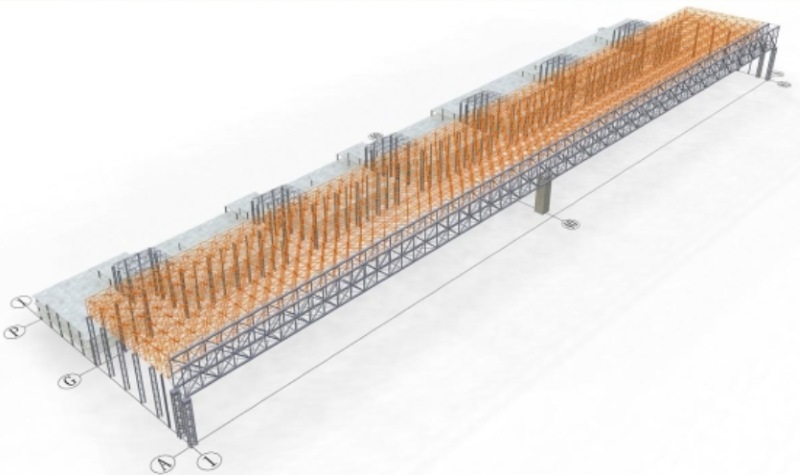

▲ Figure Roof Truss Structure 3D Model

▲ Figure Roof Truss Structure Deflection Sketches

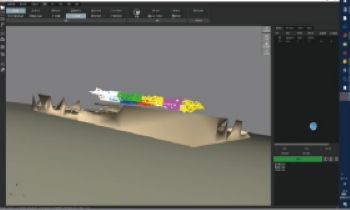

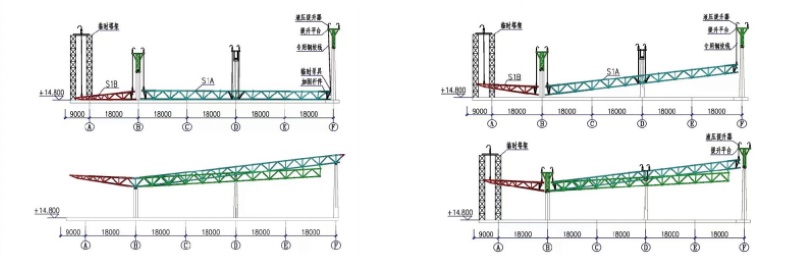

Highlight 2Overall Lifting Technology of "Proposed Design State" for Ultra-Large Span Steel Roof

The project team utilized extensive finite element construction simulations, ultra-large hydraulic synchronous lifting technology, and zonal cumulative lifting processes, supplemented by various types of combined backstay lateral resistance techniques, application of transfer trusses, and monitoring technology throughout the construction process. This ensured safety during lifting and structural integrity while reducing the investment in measures and high-altitude operations, thus efficiently and safely completing this extremely challenging lifting task.

▲ Figure Proposed Design State Overall Enhancement Technology for Super Large Span Steel Roofs

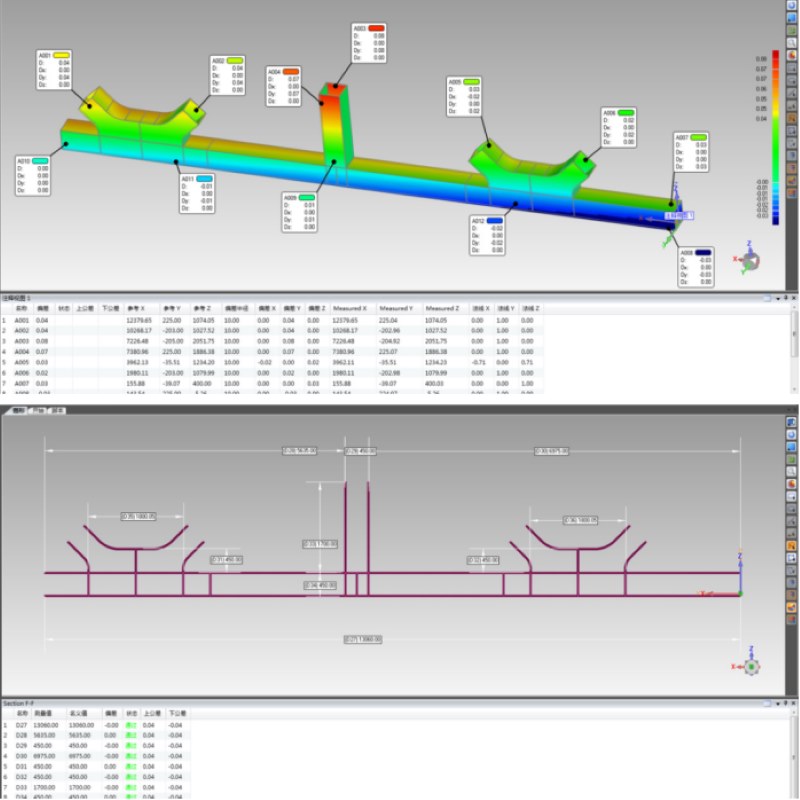

Highlight 3Virtual Pre-Assembly Technology for Complex Steel Structures

The hangar section of the project required a vast number and variety of steel structure components. To strictly control the factory precision of the lifted steel structure components and ensure accurate on-site installation, the project team employed virtual pre-assembly technology, simulating the assembly process of components on a computer. This ensured that the dimensions and positions of each part met design requirements, thus guaranteeing the quality and performance of the components, reducing errors during actual construction, and avoiding material waste and rework caused by size mismatches or assembly errors.

▲ Figure Comparison of measured component drawings and theoretical model drawings

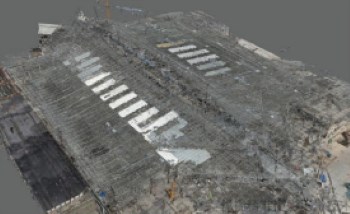

Xiamen Xiang'an Airport Terminal Area Project, Section 1The construction area of the Xiamen Xiang'an Airport terminal zone's first section is 354,000 square meters, with a building height of 47.95 meters, making it a rare island-type airport globally. The terminal roof's steel structure is divided into three areas for lifting. Among them, the total weight of the first section's steel structure roof is 2,550 tons, covering an area of approximately 29,100 square meters, with a lifting height of 14 meters; the second section's steel structure roof weighs 1,533 tons, covering about 18,800 square meters, lifted to 46.6 meters; the third section's steel structure roof weighs 2,626 tons, covering around 30,400 square meters, with a lifting height of 11 meters.

Complex Roof Structure and Advanced Photogrammetry Technology

To address the limitations of conventional point-by-point manual measurement of truss deformation, such as restricted visibility, low efficiency, and poor presentation, the project collaborated with Shenzhen University to develop advanced photogrammetry technology. This technology utilizes drones for aerial data collection of the roof truss structure, generating real-world models with millimeter-level precision. Customized software extracts deformation data, significantly improving monitoring accuracy and coverage of measurement points, providing a reference for subsequent deformation monitoring of similar roof structures.

Highlight 2

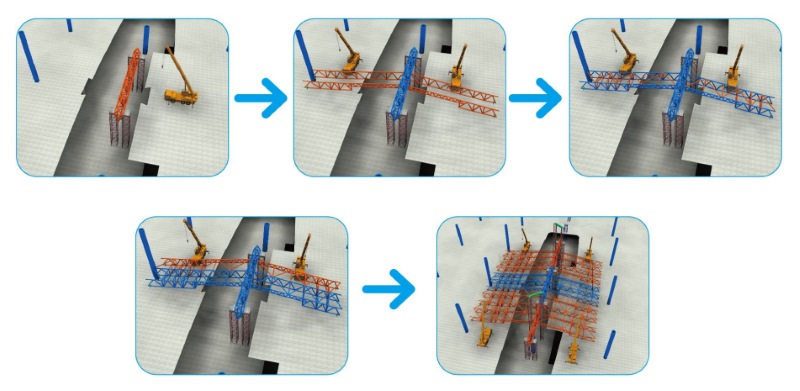

Integrated Lifting Technology for Multi-Disciplinary Roof Systems

The project team utilized BIM technology to modularly divide the roof's electromechanical pipelines, purlins, and walkways, allowing for rapid ground installation and synchronized lifting with the roof. This approach resolved issues of non-collaboration in deep design among multiple disciplines, difficulties in coordinating specialized construction, and delays in resource organization, while also reducing risks associated with high-altitude work and achieving rapid construction of the steel roof system.

▲ Integrated lifting of roof purlins

Highlight 3

Ultra-Large Hydraulic Synchronous Lifting Technology

Based on the characteristics of the steel structure roof, the project employed a combination technical scheme for the middle roof, which includes "in-situ assembly of floor slabs + sectional cumulative hydraulic synchronous lifting + aerial rotation," while the lower roof used "sectional block hoisting." By controlling the lifting speed of the lifters, uneven lifting of the truss was achieved, ensuring precise adjustment of the design posture and avoiding construction safety and quality issues such as high-altitude welding, effectively controlling deformation and ensuring structural stability.

Highlight 4

Virtual Pre-Assembly Technology for Steel Structures

The project's steel structure roof truss adopted virtual pre-assembly technology, utilizing 3D design software to control the actual 3D coordinates of segmented component control points. This process simulates the assembly to form a contour model on the computer, which is then compared and fitted with the theoretical model from the deep design. After correction, modification, and simulated assembly, the technology efficiently meets precision requirements, significantly enhancing construction efficiency.

Why ZHM Huawu Ultra-Large Span Steel Roof Structure for Aircraft Hangars ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Ultra-Large Span Steel Roof Structure for Aircraft Hangars ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com

- Pre:None

- Next:Adding photovoltaic panels to 2025/6/29