Adding photovoltaic panels to light steel roofs, how to reinforce purlins?

Previously, ZHM shared methods for reinforcing main structures like steel columns and main beams after adding photovoltaics to the roof. Today, we will share several methods for reinforcing purlins.

Common Reinforcement Methods and Comparison of Advantages and Disadvantages

Reinforcement of steel columns needs to consider both effectiveness and economy. Common methods are as follows:

1. Purlin Section Enlargement Reinforcement Method

Method: Add a full-length or partial L-shaped edge purlin next to the existing purlin to share the load together.

Advantages: Simple construction, no need to replace original components, and no need to remove tie rods.

Disadvantages: Limited increase in bearing capacity.

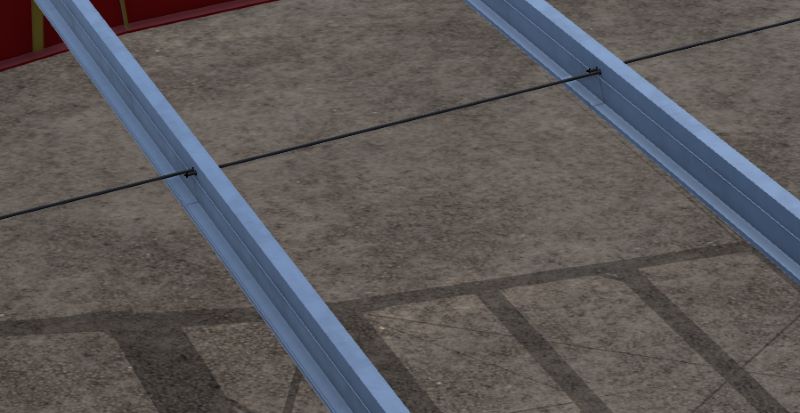

2. Continuous Purlin Reinforcement Method

Method: Add embedded nested purlins at the supports of the existing simply supported purlins, changing from simply supported beams to continuous beams to reduce mid-span bending moments.

Advantages: Simple construction, no need to replace original components, and no need to remove tie rods.

Disadvantages: Only suitable for reinforcing simply supported purlins.

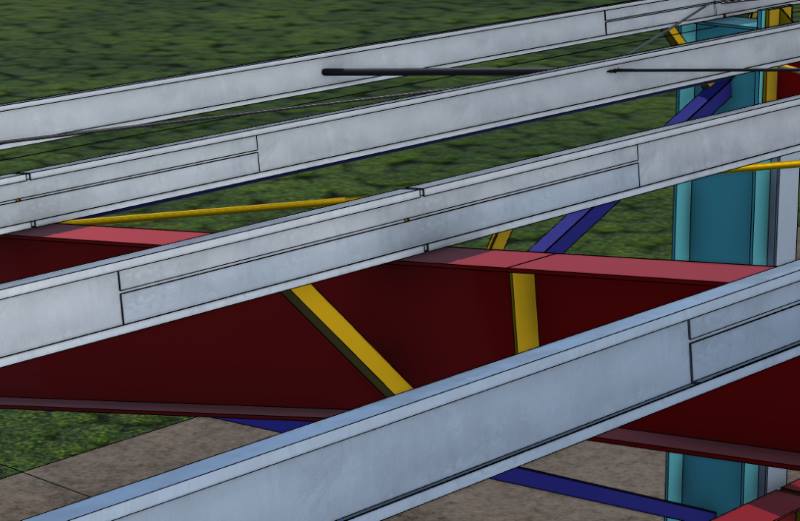

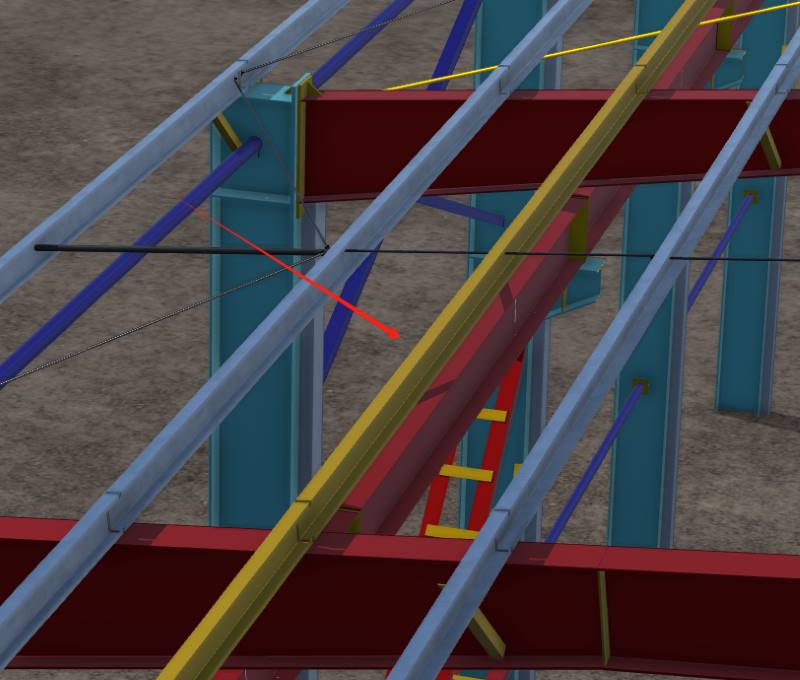

3. Truss Purlin Reinforcement Method

Method: Arrange diagonal web members and lower chord members below the existing purlins to form a stable truss system to share the load.

Advantages: High overall stiffness and significant increase in bearing capacity.

Disadvantages: Higher cost and complicated construction.

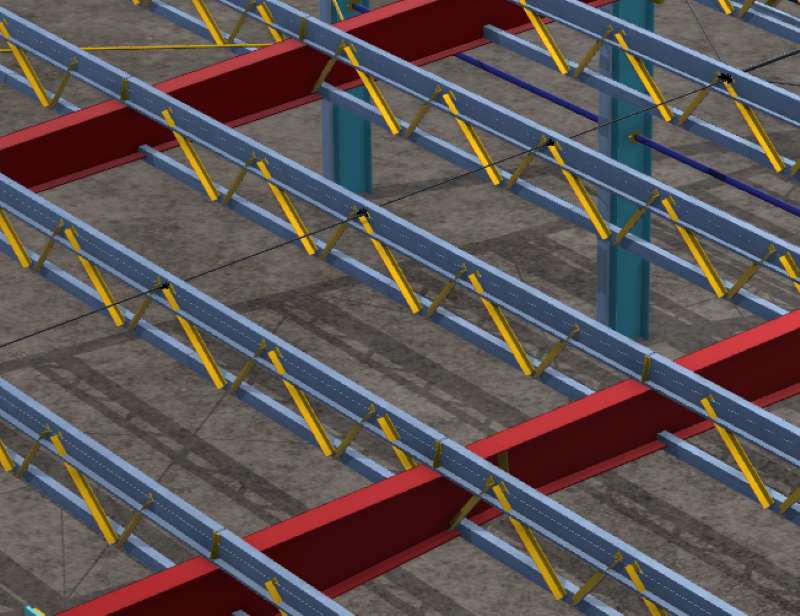

4. Increased Purlin Reinforcement Method

Method: Add a row of purlins between the existing purlins to share the load.

Advantages: Significant increase in bearing capacity.

Disadvantages: Higher cost, complicated construction, and requires removal of roof tie rods.

Precautions

1. Before reinforcement, it is necessary to verify the bearing capacity of purlins and main structures to avoid local strengthening leading to overall failure.

2. The connection points of the photovoltaic support must be specially designed to avoid stress concentration (e.g., adding stiffeners or distributing load nodes).

3. Construction should comply with the structural requirements for tie rods and braces in Section 9.3 of the "Code for Steel Structure" (spacing, diameter, etc.).

Why ZHM Huawu Metal Reinforced Purlins For Photovoltaic Roof Panels ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Reinforced Purlins For Photovoltaic Roof Panels ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com

- Pre:None

- Next:What is a Slug and Why do we N 2025/5/23