Analysis of Structural Safety Hazards and Engineering Accidents of Coal Sheds (Material Sheds)

Steel structure grid coal sheds (material sheds) play an increasingly important role in industrial storage buildings in large enclosed spaces. With the growing strictness of environmental protection requirements, the demand for large-scale storage and fully enclosed management of coal piles in industries such as large coal mines, coking, metallurgy, electricity, cement, and petrochemicals is continuously rising. The large-span grid structure has become the preferred choice for coal shed (material shed) construction due to its spaciousness, lightweight, flexible design, and rapid construction characteristics. However, with the widespread promotion and application of this structure, collapses of coal sheds (material sheds) have also occurred frequently, raising alarms.

On September 10, 2021, a partial collapse occurred at a dust and noise reduction shed of a company in Chengdu, Sichuan Province, resulting in 4 fatalities and 18 injuries. On March 31 of the same year, a grid collapse occurred at a company in Qingdao, Shandong Province, causing 1 death and 7 injuries. Looking back at history, similar accidents have frequently occurred: on June 8, 2019, a coal storage shed grid collapsed at a coal company in Etuoke Banner, Inner Mongolia, resulting in 3 deaths and 1 injury; on August 12, 2018, a partial collapse occurred at a canopy of a company in Emeishan, Sichuan Province, leading to 5 deaths and 2 injuries on the spot. These accidents not only caused severe losses to enterprises due to production line shutdowns and casualties but also resulted in adverse social impacts. This article aims to briefly analyze the problems existing in coal shed (material shed) structures in conjunction with relevant engineering cases, with the goal of reminding everyone to pay high attention and jointly prevent similar accidents from happening again.

Common Problems in Coal Shed (Material Shed) Structures

Through extensive engineering practice, experimental analysis, and accident investigations, ZHM Huawu Steel Structure has found that coal shed (material shed) grid structures commonly have the following issues:

Common Problems in Coal Shed (Material Shed) Structures

In the actual use of coal shed (material shed) grid structures, ZHM Huawu Steel Structure frequently encounters the following problems:

Incomplete design content. The design fails to strictly follow relevant specifications, such as insufficient wind resistance level settings, improper construction measures in key areas like eaves and surroundings, or lack of safety assessments of the structural condition.

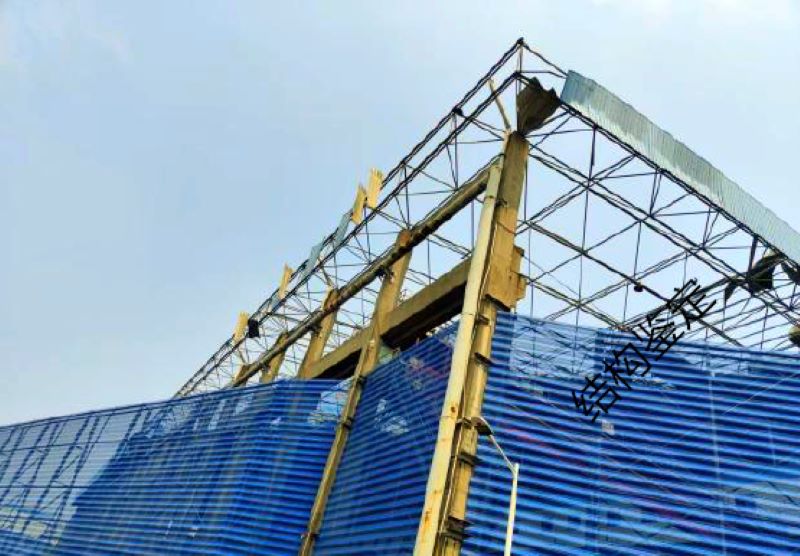

Non-standard construction processes and supervision systems.This includes using substandard materials, non-standard construction methods, such as excessive bending of members, insufficient high-strength bolt connections, and poor weld quality. Additionally, deviations during installation, arbitrary increases or decreases of members and supports can adversely affect the structure.

Impact of the usage environment. Due to long-term exposure to environmental corrosion, temperature changes, and wind loads, the structure and materials may gradually suffer damage and performance degradation, potentially leading to structural failure.

Improper usage and maintenance. For example, arbitrary increases in load, insufficient daily management and maintenance, and improper stacking of materials can lead to deformation and damage of supports or members. Failure to promptly detect and address existing defects and damages may also trigger secondary disasters.

Typical Cases of Structural Inspection and Assessment of Coal Sheds (Material Sheds)

Case 1: A dry coal shed at a power plant, whose roof structure uses a positive four-corner conical bolt ball joint steel grid, supported by reinforced concrete columns, with concrete walls between the columns. The coal shed is 216 meters long from north to south and 103 meters wide from east to west. The assessment revealed:

(1) Rust on the reinforcement, local collisions, or improper construction led to swelling, spalling, and damage of the concrete in the columns and shear walls.

(2) Some supports exhibited tilting and eccentricity issues, with support nuts not tightened, and insufficient reserved length of anchor bolt rods, preventing reliable connections. Additionally, some support bolts only used single nuts, which did not meet design requirements, and stiffening rib plates also showed signs of bending deformation.

(3) Common issues included missing members, disconnections at support connections, longitudinal cracking, bending deformation of members, and looseness of member connections to bolt ball sleeves.

(4) Bending deformation of purlins, cracking or disconnection of purlin supports, and missing or loose connection bolts between purlins and supports led to unreliable connections. Furthermore, the node plates at the purlin connection points also showed deformation. Additionally, there were local damages, missing sections, disconnections, or deformation of the roof panels.

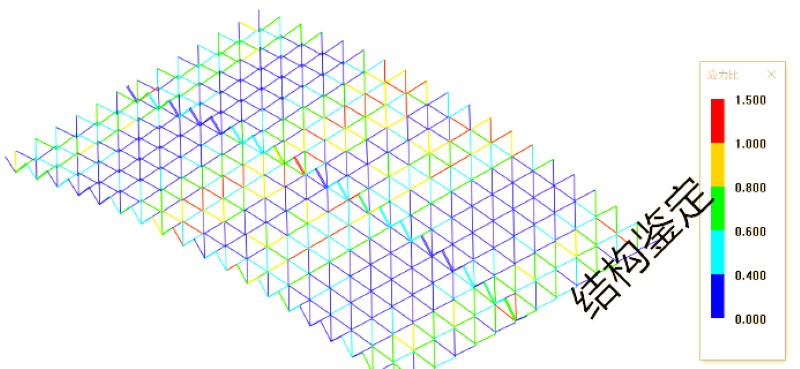

(5) After careful calculations, it was found that the load-bearing capacity of over 1,500 members in the upper grid structure did not meet the requirements of current national standards.

Exploring the Interior of the Structure

Entering the interior of the coal shed (material shed), ZHM Huawu Steel Structure can explore the details of its structure. The first thing that catches the eye is the intricate steel truss, which are connected by precise bolt ball nodes, collectively supporting the entire roof. These steel trusses are firmly supported by reinforced concrete columns, with cleverly placed concrete walls between the columns that enhance the structure's stability while providing necessary separation within the shed. Spanning 216 meters in length from north to south and 103 meters in width from east to west, every inch of space embodies the wisdom and craftsmanship of structural engineers. However, beneath the seemingly solid exterior lies numerous issues that cannot be overlooked.

Inclination and Eccentricity of Supports

In the internal structural exploration of the coal shed (material shed), ZHM Huawu Steel Structure must pay attention to a key issue: the inclination and eccentricity of the supports. These problems may seem minor, but they pose a potential threat to the overall stability of the structure. The inclination and eccentricity of the supports can affect the force distribution of the steel truss and may lead to deformation of the entire structure, thereby impacting the safe use of the coal shed. Therefore, sufficient attention must be given to these detail issues during the structural design and construction process to ensure that the coal shed can safely and stably serve production and daily life.

Disconnection at the Connection of Members and Supports

In the structure of the coal shed (material shed), the connection between members and supports is a crucial link. However, for various reasons, this connection may sometimes become disconnected. This not only affects the integrity of the structure but also further leads to issues of support inclination and eccentricity, potentially resulting in the instability of the entire structure. Therefore, in structural design and daily maintenance, close attention must be paid to the condition of this connection to ensure its stability and reliability.

Loose Sleeve at the Connection between Members and Lower Chord Ball Nodes

In the structure of the coal shed (material shed), the connection between members and lower chord ball nodes is equally important. However, if the sleeve at the connection is not properly tightened, it may lead to a loose connection, thereby affecting the overall stability of the structure. Therefore, after the structure is completed, all connections must be carefully inspected to ensure that the sleeves are tightened to the specified torque, thus ensuring the stability and safety of the structure.

Longitudinal Fracture of Members

In the structure of the coal shed (material shed), the integrity and stability of members are crucial. However, if a member experiences a longitudinal fracture, it will directly threaten the overall safety of the structure. Such fractures may be caused by material defects, overload, or improper use. Therefore, during the use of the structure, regular safety inspections should be conducted to timely identify and address potential fracture risks, ensuring the continued safety and stability of the structure.

Longitudinal Fracture at the Ends of Members

In the members of the coal shed (material shed) structure, longitudinal fractures at the ends are a common and potentially dangerous situation. These fractures may be caused by various factors, including defects in the material itself, use beyond design load, and improper daily maintenance. To ensure the safety and stability of the structure, detailed safety inspections of the members must be conducted regularly to timely identify and address such fracture issues.

Deformation of Members

In the members of the coal shed (material shed) structure, deformation is also a significant issue that cannot be ignored. Deformation may result from various factors, such as material aging, overload use, and uneven foundations. To ensure the overall stability of the structure, regular monitoring of member deformation is essential, with timely measures taken to correct or address deformation issues.

Fracture at the Connection between Purlins and Nodes

In the structure of the coal shed (material shed), fractures at the connection between purlins and nodes are also a concern. Such fractures may occur due to long-term use, material fatigue, or inadequate design. To ensure the safety and stability of the structure, regular inspections of this critical connection point must be conducted to timely identify and address fracture issues.

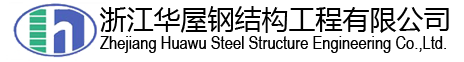

In the structure of the coal shed (material shed), the dimpling deformation of roof panels is also an issue that cannot be overlooked. This deformation may be caused by long-term heavy loads, material aging, or uneven foundations. To ensure the safety and stability of the structure, it is crucial to conduct regular inspections of the deformation of roof panels to timely identify and take appropriate repair measures.

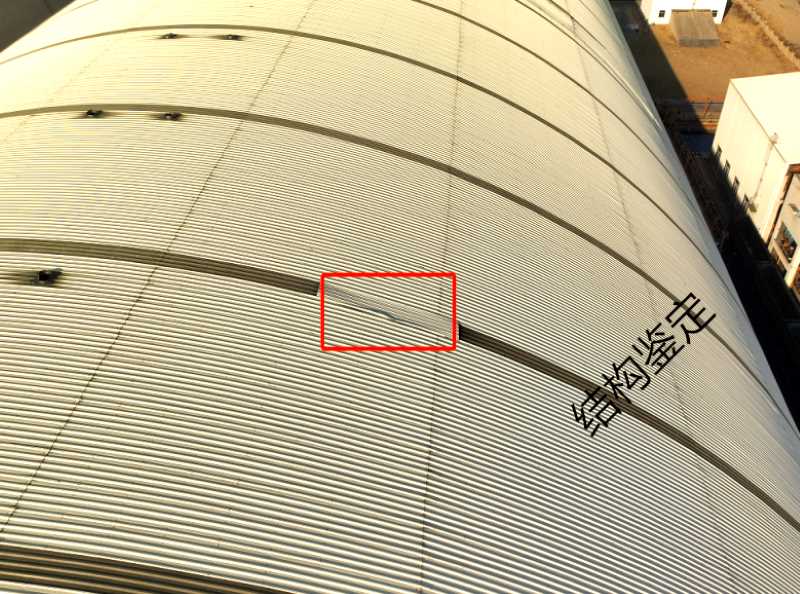

Structural Calculation Results

In the evaluation of the dry coal shed structure at a certain power plant, ZHM Huawu Steel Structure identified the following major issues:

First, the concrete structural components have suffered varying degrees of damage. Due to the corrosion of the rebar, the concrete has shown signs of swelling, cracking, and spalling, with some stirrups severely corroded or even broken. Additionally, collisions or construction quality issues have also led to localized damage, spalling, and exposed rebar in the concrete columns. Meanwhile, the quality of concrete pouring was poor, with exposed aggregates.

Secondly, the truss members are also facing severe damage. Some members have significant localized corrosion, with a few even perforated by rust. There are also issues with loose connection sleeves and bent deformations of the members.

Furthermore, the enclosure system is also severely damaged. The roof panels at the gutters are generally rusted, with some areas even perforated. In certain regions, the purlins have overall instability and deformation. Additionally, the connections between the main purlins and the secondary purlins, as well as between the main purlins and the truss, are unreliable.

Finally, after calculations, ZHM Huawu Steel Structure found that the load-bearing capacity of nearly 200 truss members does not meet the current national standards. At the same time, the load-bearing capacity of the roof purlins is also severely below standard.

Upon delving into the structure, ZHM Huawu Steel Structure discovered numerous issues that urgently need to be addressed. First, the damage to the concrete structure cannot be ignored; not only are there signs of swelling and spalling, but some stirrups have also fractured due to corrosion. Second, the truss members are similarly severely damaged, with localized corrosion and even perforation, compounded by loose connection sleeves and deformations of the members, posing serious safety risks to the entire truss system. Additionally, the enclosure system is fraught with problems, including rust damage to the roof panels at the gutters, instability and deformation of the secondary purlins, and the unreliable connections between the roof purlins and the truss, all of which greatly affect the safety and lifespan of the building. Lastly, through detailed calculations, ZHM Huawu Steel Structure found that nearly 200 members in the truss structure do not meet standards, and the load-bearing capacity of the roof purlins is also severely insufficient, posing significant challenges to the safe operation of the power plant.

**Corrosion of Concrete Columns and Broken Stirrup Issues**

**Perforation of Members Due to Corrosion**

In the detailed observation of the structure, ZHM Huawu Steel Structure found that the members have also suffered severe corrosion, with some areas even showing perforation. This not only damages the integrity of the members but may also adversely affect their load-bearing performance, threatening the safety of the entire structure.

In the thorough observation of the structure, ZHM Huawu Steel Structure found that the sleeves at the connections of the members are loose. This situation may not only compromise the stability of the member connections but could also further lead to structural safety issues, requiring high attention.

**Overall Instability and Deformation of Purlins in Certain Areas**

In the detailed structural analysis, ZHM Huawu Steel Structure discovered that certain areas of the purlins have experienced overall instability and significant deformation. This condition not only affects the normal functioning of the purlins but may also pose a threat to the overall safety of the structure, necessitating timely and effective measures for resolution.

**Lack of Stability in Purlin Connections**

In the in-depth structural analysis, ZHM Huawu Steel Structure found issues with the connection methods of the purlins, lacking necessary stability. This unstable connection condition not only affects the normal use of the purlins but may also adversely impact the overall stability of the structure. Therefore, it is essential to emphasize and take measures to strengthen the stability of the purlin connections.

**Localized Wind Damage to the Enclosure Structure**

Under the influence of wind forces, localized areas of the enclosure structure have experienced wind-induced damage. This damage not only affects the aesthetics and functionality of the building but may also pose a threat to the overall structural safety. Therefore, effective measures need to be taken to enhance the wind resistance of the enclosure structure and prevent similar damage from occurring again.

**Conclusion**

Appendix: Performance of some coal shed (material shed) structural projects

2021 Baogang Storage Center Material Yard Enclosed Shed Structural Reliability Assessment

Subsequently, ZHM Huawu Steel Structure received the structural reliability assessment project for the enclosed shed at the Baogang Storage Center. Similar to the previous project, ZHM Huawu Steel Structure will conduct detailed testing and evaluation of the shed’s structure to ensure its stability and reliability, providing robust technical support for the Baogang Storage Center.

2021 Shanxi Tongcai Industrial and Trade Co., Ltd. Raw Material Yard Shed Structural Reliability Assessment

In addition, in 2021, ZHM Huawu Steel Structure also conducted a structural reliability assessment of the raw material yard shed for Shanxi Tongcai Industrial and Trade Co., Ltd. Utilizing professional knowledge and technology, ZHM Huawu Steel Structure performed a comprehensive inspection and evaluation of the shed’s structure, aiming to ensure its stability and reliability, providing a solid guarantee for the enterprise's safe production and environmental protection efforts.

2021 Tianjin Guoneng Jinneng Thermal Power Co., Ltd. Phase I Coal Shed Structural Reliability Testing and Assessment

ZHM Huawu Steel Structure further expanded its business scope by undertaking the structural reliability testing and assessment of the coal shed for Tianjin Guoneng Jinneng Thermal Power Co., Ltd. Phase I. This project requires ZHM Huawu Steel Structure to conduct a comprehensive inspection and evaluation of the coal shed’s structure to ensure its safety and stability, meeting the needs for the enterprise's daily operations and safe production. ZHM Huawu Steel Structure understands the importance of this task and will use professional knowledge and technology to provide accurate and reliable testing and assessment services for Tianjin Guoneng Jinneng Thermal Power Co., Ltd.

2022 Guangzhou Zhongdian Lixin Thermal Power Co., Ltd. Dry Coal Shed Testing and Assessment

After successfully completing the structural reliability testing and assessment of the coal shed for Tianjin Guoneng Jinneng Thermal Power Co., Ltd. Phase I, ZHM Huawu Steel Structure extended its business to Guangzhou Zhongdian Lixin Thermal Power Co., Ltd. In 2022, ZHM Huawu Steel Structure undertook the testing and assessment task for the dry coal shed of this company, aiming to comprehensively evaluate its structural condition and ensure its safety and stability during use.

2023 Datang Xiangtan Power Generation Co., Ltd. No. 1 Coal Yard Dry Coal Shed Testing

With the continuous expansion of its business scope, in 2024, ZHM Huawu Steel Structure faced new challenges. This year, ZHM Huawu Steel Structure was commissioned to conduct structural testing of the dry coal shed at Datang Xiangtan Power Generation Co., Ltd. No. 1 coal yard. ZHM Huawu Steel Structure understands the significance of this task and will employ excellent professional technology to provide detailed and comprehensive testing services, helping to ensure the safety and reliability of the coal shed structure.

2025 New Chapter in Dry Coal Shed Testing

Why ZHM Huawu Metal Analysis of Structural Safety Hazards and Engineering Accidents?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Analysis of Structural Safety Hazards and Engineering Accidents ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com

- Pre:None

- Next:Ultra-Large Span Steel Roof St 2025/7/28