Steel Structure Spiral Staircases | ZHM,China Manufacturer Factory Supplier

Meticulously Crafted, Perfectly Combined in an Instant — [ZHM Huawu Steel] Art of Steel Structure Spiral Staircases

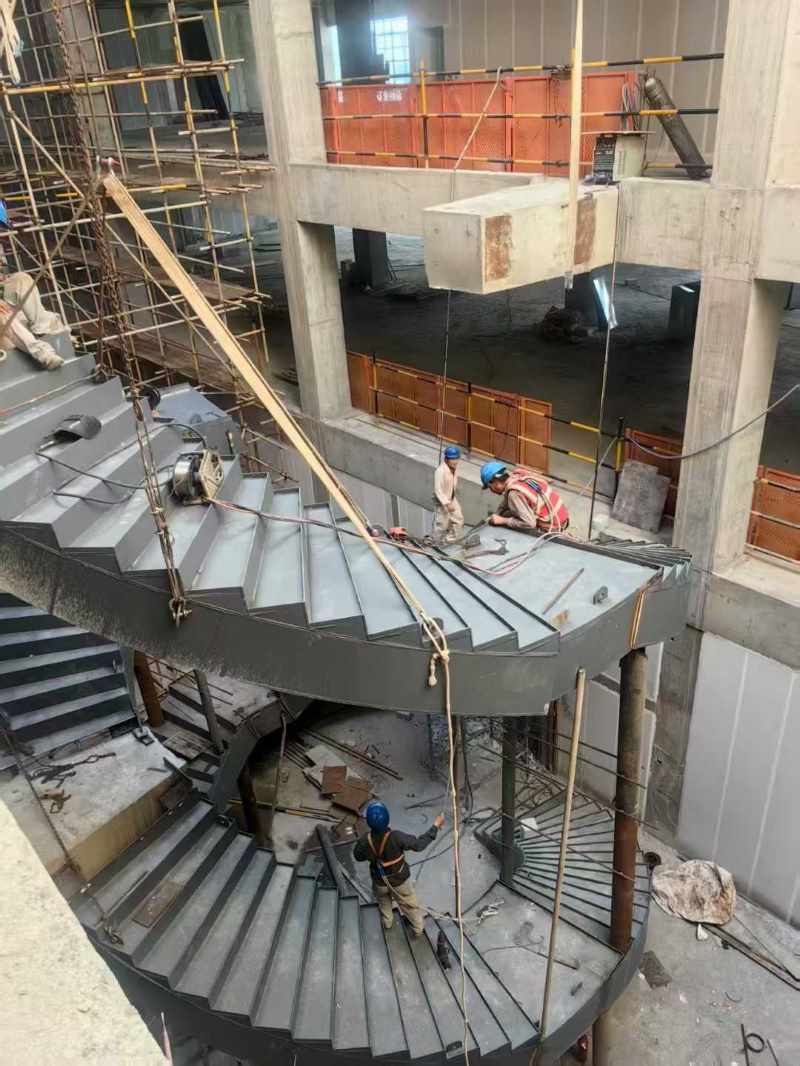

What you see is the efficient and smooth installation process on-site, marveling at the perfect positioning of the steel structure spiral staircase.

"Production always precedes installation" — this is not only our dedication to quality but also the strongest commitment to your project timeline.

Craftsmanship conquering challenges: Our "slowness" is to achieve "speed" on-site.

1. Precise Calculation and Layout of Three-Dimensional Curvature

Challenge: The spiral staircase is a complex three-dimensional hyperbolic component, with each step and each section of railing having unique curves, angles, and twists, requiring extremely high accuracy in data.

Our Highlight: Using advanced BIM three-dimensional modeling and CNC laser layout technology, we convert design blueprints into digital models with millimeter-level precision. This ensures that each component has completed "virtual pre-installation" in the factory, eliminating the risk of "not fitting" on-site from the source.

Challenge: Cold bending of high-strength steel requires immense pressure, easily causing rebound and internal stress during the process, leading to deviations between the actual shape of the finished product and the design.

Our Highlight: With experienced technicians and specialized bending equipment, we precisely control the force and angle of each bend, and eliminate internal material stress through our processes. This ensures that each curved beam is smooth and natural, with perfect uniformity in curvature, laying the foundation for seamless connections.

3. Millimeter-Level Welding and Polishing Process

Challenge: Controlling thermal deformation during welding is a well-known challenge in the industry, especially at multi-segment curve joints where deformation can accumulate and amplify.

Our Highlight: Using special processes like segmented symmetrical welding, we minimize thermal deformation to the greatest extent. All welds undergo 100% non-destructive testing, followed by meticulous manual polishing by artisans, making the welds blend seamlessly with the base material, achieving a silky smooth touch and visual appeal.

4. Rigorous Factory Pre-Assembly and Numbering Management

Challenge:With hundreds of components arriving on-site, how can we ensure quick identification of the correct positions for installation?

Our Highlight: Before leaving the factory, key components undergo simulated pre-assembly to check compatibility. All components are assigned clear, unique identification numbers that correspond one-to-one with the installation drawings. This means that on-site workers can "assemble like LEGO," following the drawings to greatly enhance installation efficiency.

Conclusion: Choosing us means choosing not just a product, but a reliable solution.

The "smoothness" of on-site installation comes from the "adequacy" of prior preparation.

This is why our clients say: "Your staircases are the smoothest part of our site installation!"

Let art and precision perfectly combine, making installation the ultimate magnificent display.

Keywords: "Spiral Staircase," "Steel Structure Staircase," "Custom Staircase," "Precision Manufacturing," "BIM Technology"

Why ZHM Huawu Metal Steel Structure Spiral Staircases?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Steel Structure Spiral Staircases ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com

精工雕琢,方能瞬间合璧——[ZHM华屋钢构 ] 钢构螺旋楼梯艺术

当您的现场安装日行千里,是因为我们的工厂制作精益求精。

您所见的,是现场高效流畅的安装过程,惊叹于钢结构螺旋楼梯的完美就位。

您未见的是,这“轻松”背后的极致专注与漫长打磨。

“制作,永远跑在安装之前”——这不仅是我们对品质的执着,更是对您项目工期最坚实的承诺。

匠心制造,攻克难点:我们的“慢”,是为了成就现场的“快”

钢结构螺旋楼梯被誉为“空间中的雕塑”,其制作过程远非简单的弯曲焊接。我们深知,每一个毫米的精度,都是现场能否“丝滑”安装的关键。

我们的制作难点与核心亮点:

1. 三维空间曲率精准计算与放样

难点: 螺旋楼梯是复杂的三维双曲线构件,每一节踏板、每一段栏杆的弧度、倾角、扭度都独一无二,对数据的精确性要求极高。

我们的亮点: 采用先进的BIM三维建模与数控激光放样技术,将设计蓝图转化为毫米级精度的数字化模型。确保每一个构件在工厂内都已完成“虚拟预安装”,从源头上杜绝现场“装不上”的风险。

2. 高精度冷弯成型与应力控制

难点: 高强度钢材的冷弯成型需要巨大压力,过程中极易产生回弹和内部应力,导致成品实际形状与设计出现偏差。

我们的亮点: 凭借经验丰富的技师和专业弯管设备,我们精准控制每一次弯折的力度与角度,并通过工艺消除材料内应力。确保每一段弧形梁都流畅自然,弧度完美统一,为实现无缝对接打下基础。

3. 毫米级的焊接与打磨工艺

难点: 焊接的热变形控制是行业公认的难题,尤其是在多段曲线拼接处,变形会累积放大。

我们的亮点: 采用分段对称焊接等特殊工艺,最大限度减少热变形。所有焊道经过百分百无损探伤检测后,由工匠进行纯手工精细打磨,使焊缝与母材浑然一体,成就光滑如丝的触感与视觉美感。

4. 严谨的工厂预组装与编号管理

难点: 上百个构件运抵现场,如何确保快速找到正确位置进行安装?

我们的亮点: 在出厂前,关键部件会在工厂进行模拟预组装,检验配合度。所有构件均配有清晰唯一的身份编号,并与安装图纸一一对应。这意味着现场师傅如同“拼装乐高”,按图索骥,极大提升了安装效率。

结论:选择我们,您选择的不仅是产品,更是一套可靠的解决方案

我们宁愿在背后花费更多的时间去打磨、去校验,也要确保您的项目现场省时、省力、省心。

现场安装的“快”,源于工厂制作的“精”。

现场安装的“顺”,源于前期准备的“足”。

这正是为什么我们的客户会说:“你们的楼梯,是我们工地安装最顺利的环节!”

让艺术与精密完美结合,让安装成为最终的华丽展示。

—— [ZHM华屋钢构],专注于打造值得等待的钢结构艺术精品。

关键词:“螺旋楼梯”、“钢结构楼梯”、“定制楼梯”、“精密制造”、“BIM技术”